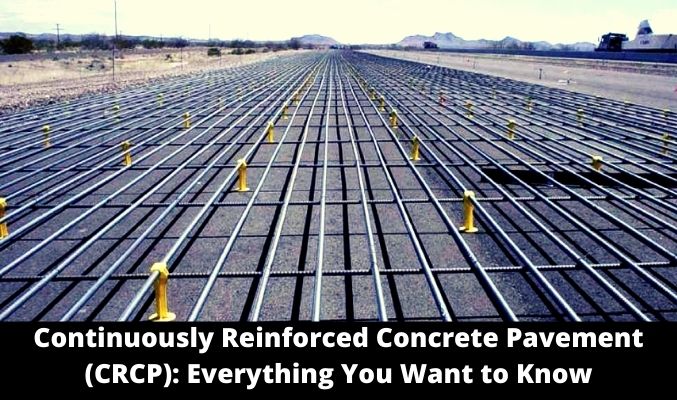

Continuously Reinforced Concrete Pavement or CRCP is a type of rigid pavement, employed in highway construction owing to its host of benefits. The pavement forms transverse cracks at close intervals due to the continuous reinforcement, which itself results from the change in concrete volume. Ideally, a thoroughly designed CRCP that’s built using superior quality materials can keep the mentioned cracks tightly closed, thereby minimizing water penetration and other similar problems.

There’s a list of pros and cons of Continuously Reinforced Concrete Pavement that construction companies consider in their decision-making. While CRCP is a popular choice for highway construction, it has some limitations as well.

CRCP, comparatively, requires less maintenance. This means there’s low maintenance cost. Since there are fewer joints and tightly closed transverse cracks, water penetration can be reduced as well. CRCP can adeptly handle heavier truck loading and volume. And while its initial cost is high, it has a longer life cycle, which keeps the overall cost in the long run low.

The benefits mentioned, the limitations of CRPC show up when the conversation shifts to conventional roads. With local roads, accessing to maintain the utilities underneath the roadbed can damage CRCP. Furthermore, rigid pavement is an expensive option for parking areas.

A range of materials is used in CRCP, including concrete and steel (steel bar, wire fabric). What’s important to note is the defined specification of these materials that need to be maintained to ensure a superior quality outcome. For instance, with concrete, dense and low permeability concrete mix is required with a maximum water content ratio of 0.42 to 0.45. Similarly, with steel, which is used in steel bar and fabricated wire mesh forms, specific grades need to be selected based on strength properties. In all, based on the application and end result, the technical specifications for the materials need to be fixed accordingly.

The design of CRCP is based primarily on the requirements of individual projects. At large, factors like tensile strength of concrete, expected temperature differential, shrinkage coefficient of the concrete, duration, and frequency of application, and various other factors influence the design. The CRCP design engineers focus on the changes of several inputs like soil type, traffic, lane width, material properties, base type, slab thickness, and more.

In recent times, there have been new developments on the design front of CRCP with the intent to attend to its limitations and challenges. For instance, many construction companies now expect a design where the pavement doesn’t have transverse steel. This will help reduce steel and contraction joints. Companies are also looking for expanding cement that can help control concrete shrinkage, thereby preventing the cracks.

While Continuously Reinforced Concrete Pavement is a very popular option for construction companies, it has its gaps. The newer designs hope to address these gaps, double down on the benefits of CRCP, and make this pavement an ultimate choice.