Quality and factual data is the essence of modern business culture which requires good infrastructure. Today, an organization must evolve in modernizing and creating new networks in order to get a fully efficient and target based data centers.

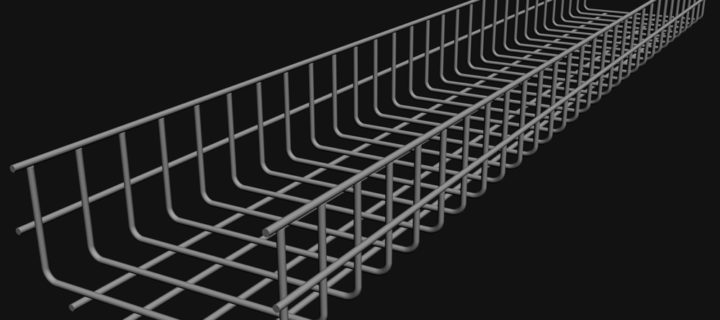

Wire mesh cable trays can be used to provide the flexibility, support as well as cooling capabilities to the cables. One of the main benefits of a wire mesh tray is that it’s cheaper and quicker to install. The flexibility provided by being able to create fittings on site can be invaluable especially when you consider just how quickly these bends and fittings can be made. Its design allows better air circulation and heat dissipation thus reducing numerous potential problems caused by overheating cables. Wire mesh cable trays are a lot lighter than regular perforated sheet cable trays and hence cost effective for similar load ratings.

One should never overload cable trays, also only that much cable trays should be used which is required otherwise it will be bulky and harder to move.

One must plan cable tray installation as per plan of Cabling pathways ,Rack density

Type/count/diameter of cables, End equipment cable entry,Choose the coating material wisely i.e. Electroplated zinc or powder coating and Room height.

If these factors are not considered before installation problems like short circuits, voltage variances, signal disturbances and complete system resets can take place which could prove to be a very costly affair.

One can’t afford a data centre which is outdated by any sort as it acts as the beacon of knowledge for the business; however there are some simple steps which can be taken to increase the efficiency of network centers.

Wire mesh cable trays are a lot lighter than regular perforated sheet cable trays and hence cost effective for similar load ratings. It finds its applications in power plants, airports, hospitals, substations, and housing projects etc.

Regular Cleaning of trays is not required as no dirt or waste gets accumulated on them because of its design.

One of the main benefits of wire mesh tray is that its cheaper and quicker to install. The flexibility provided by being able to create fittings on site can be invaluable especially when you consider just how quickly these bends and fittings can be made.

Its design allows for better air circulation and heat dissipation thus reducing numerous potential problems caused by overheating cables.

The edge wires are safely T-welded to provide smooth surface for the cables while loading and protects them from cuts due to sharp edges