Quality and factual data is the essence of modern business culture which requires good infrastructure. Today, an organization must evolve in modernizing and creating new networks in order to get a fully efficient and target based data centers.

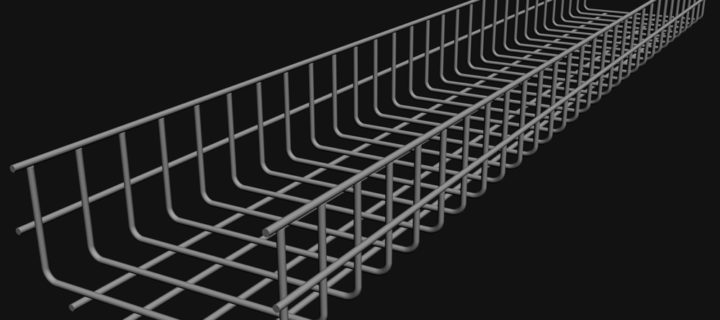

Wire mesh cable trays can be used to provide the flexibility, support as well as cooling capabilities to the cables. One of the main benefits of a wire mesh tray is that it’s cheaper and quicker to install. The flexibility provided by being able to create fittings on site can be invaluable especially when you consider just how quickly these bends and fittings can be made. Its design allows better air circulation and heat dissipation thus reducing numerous potential problems caused by overheating cables. Wire mesh cable trays are a lot lighter than regular perforated sheet cable trays and hence cost effective for similar load ratings.

One should never overload cable trays, also only that much cable trays should be used which is required otherwise it will be bulky and harder to move.

One must plan cable tray installation as per plan of Cabling pathways ,Rack density

Type/count/diameter of cables, End equipment cable entry, Choose the coating material wisely i.e. Electroplated zinc or powder coating and Room height.

If these factors are not considered before installation problems like short circuits, voltage variances, signal disturbances and complete system resets can take place which could prove to be a very costly affair.

One can’t afford a data center which is outdated by any sort as it acts as the beacon of knowledge for the business; however there are some simple steps which can be taken to increase the efficiency of network centers.

Wire mesh cable trays are a lot lighter than regular perforated sheet cable trays and hence cost effective for similar load ratings. It finds its applications in power plants, airports, hospitals, substations, and housing projects etc.

When it comes to organizing and supporting electrical wiring systems in industrial, commercial, or residential settings, selecting the right cable tray is crucial. Partnering with a trusted cable tray manufacturer offers unmatched benefits in terms of product quality, customization, and long-term performance.

As a leading cable tray manufacturer in Kolkata, we understand the unique demands of modern infrastructure. Our expertise ensures that every cable tray we produce meets stringent quality standards and offers superior durability. Whether you need perforated, ladder-type, or raceway-style trays, we provide tailored solutions that align with your project requirements.

One of the most overlooked yet essential components is the cable tray cover, which plays a vital role in protecting cables from dust, debris, and external damage. We manufacture robust covers that enhance system safety and extend the life of your wiring setup.

Choosing a dedicated manufacturer like us means gaining access to:

For safe, efficient, and future-ready wiring systems, trust a reliable cable tray manufacturer in Kolkata. Let us help you build a secure and well-organized electrical infrastructure.

Regular Cleaning of trays is not required as no dirt or waste gets accumulated on them because of its design.

One of the main benefits of wire mesh tray is that its cheaper and quicker to install. The flexibility provided by being able to create fittings on site can be invaluable especially when you consider just how quickly these bends and fittings can be made.

Its design allows for better air circulation and heat dissipation thus reducing numerous potential problems caused by overheating cables.

The edge wires are safely T-welded to provide smooth surface for the cables while loading and protects them from cuts due to sharp edges

Q1: What is a cable tray and why is it important?

A cable tray is a structural system used to support insulated electrical cables for power distribution, control, and communication. It ensures proper organization, safety, and accessibility for maintenance.

Q2: What types of cable trays do you manufacture?

We manufacture a wide range of cable trays including perforated cable tray, electrical cable tray, plastic cable tray, Profab cable tray, and trunking cable tray to suit various industrial and commercial needs.

Q3: Do you provide cable tray covers?

Yes, we supply cable tray covers to protect cables from dust, moisture, and physical damage while ensuring a neat appearance.

Q4: Can you supply cable trays in different cities?

Absolutely! We are a leading cable tray manufacturer in Chennai, cable tray manufacturer in Bangalore, cable tray manufacturer in Ahmedabad, cable tray manufacturer in Kolkata, and cable tray manufacturer in Coimbatore. We serve clients across India with timely delivery.

Q5: What is a cable management tray and where is it used?

A cable management tray organizes and routes cables efficiently in offices, industries, and IT setups. We also offer under desk cable management trays for workplace and data center applications.

Q6: Do you manufacture cable tray bends?

Yes, we produce cable tray bends in various angles and sizes to ensure smooth directional changes in cable routing systems.

Q7: How do I choose the right cable tray for my project?

The choice depends on load capacity, environment, cable type, and application. Our experts can guide you in selecting the right electrical cable tray, perforated cable tray, or plastic cable tray for your needs.